You are here :![]() » Tyre Retreading

» Tyre Retreading

RETREADING

Why use retreads?

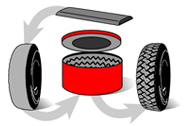

Mold-Cure (Hot)

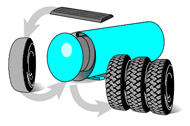

Pre Cure (Cold)

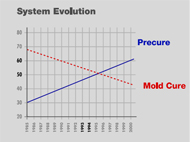

System evolution

Why Precure ?

Enduser choice

News

1- Manufacturers of bellows, expansion joints, high temperature fabric, and exotic gasketing.

GLOBAL TYRES : provides you with an experienced team of field - savy engineering professionals-you'll benefit from 22 years of hands-on...

Read More

Contact Us